Power Generation

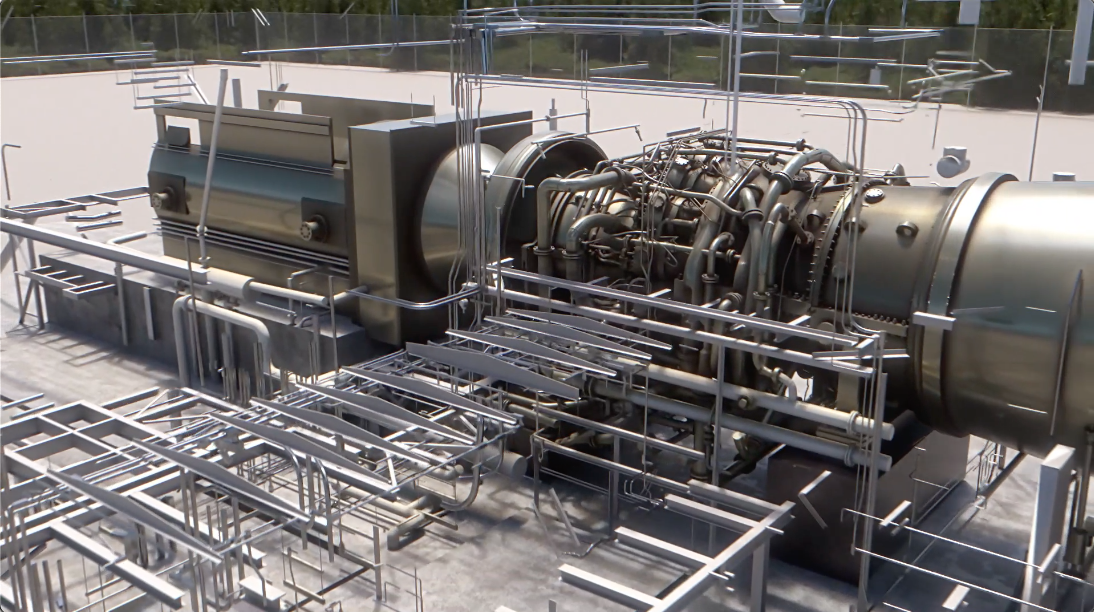

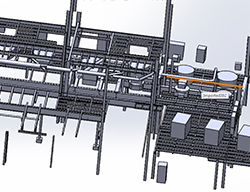

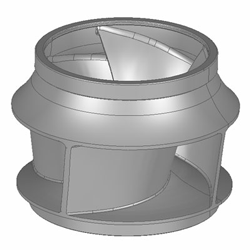

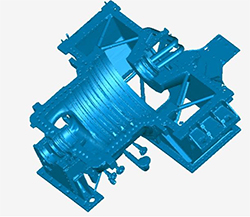

It’s no mystery why 3D scanning in the power generation industry is being embraced by an ever-greater number of OEMs and power plant engineers: 3D scanning is able to provide precise computer-aided design (CAD) models for inspecting and reverse engineering every type of power plant equipment--large or small--from turbine blades, diaphragms, and casings to hydroelectric plant impellers and even complex facility piping layouts.

NVision’s 3D scanning gives you the opportunity to digitize any and all equipment in your plant or manufacturing facility. That means when the NVision team delivers the final computer-aided design (CAD) file, you’ll have an exact model, down to every dimension, every curve and angle, of the parts and equipment. With the CAD file, you’ll be able to visualize and analyze your equipment in 3D to redesign parts, improve maintenance, reduce equipment failure (and downtime) and improve the efficiency of virtually every part and assembly in the CAD file(s). The result? Significant gains in power output and equipment operation, and reduced parts failure and maintenance. All of which translates into streamlined projects and sizable cost savings. (Our engineering services recently helped one plant converting to a new power source increase wattage output by more than 30% and save over $250,000.)

As one turbine OEM states, “Laser scanning clearly represents the future of our business and every business that depends on being able to quickly and accurately determine the geometry of a physical part.” Another reflects that before 3D scanning, “it took longer to inspect blades than it took to make them.”

Yes, the days of using calipers and other hand tools to inspect equipment are largely gone. As parts have become more complex and surface geometry more difficult to measure, non-contact optical scanning methods are far superior in their ability to fully and accurately capture the measurements of all features and dimensions

At NVision, we know power generation. We’ve provided quality inspection/measurement services to the power industry for over three decades. When we come to your plant, we’re bringing 30+ years of power plant experience to your plant. Our skilled team of technicians will quickly and efficiently scan your equipment and provide you with CAD files--perfect digital copies--that precisely capture every detail of critical parts, equipment,and assemblies, from smaller parts like turbine blades, diaphragms, couplings, casings, and impellers to larger equipment such as pumps, pumping systems, gas and steam turbine assemblies, Generators, Boilers, and even complex facility piping layouts.

From turbine assemblies to one-of-a-kind parts, NVision’s reverse engineering services can help you:

- Inspect parts for damage or to ensure they meet design specifications

- Reverse-engineer an existing turbine blade or other critical part to make design improvements.

- Analyze difficult-to-access assemblies to determine the optimal placement of sensors or other necessary instrumentation.

- Measure critical turbine blade geometry and that of related tooling in order to refurbish or replace aging legacy parts.

And much more. For over 30 years, the NVision name has been synonymous with quality work. Our experience in the power industry shows...in the results we deliver and the customers we keep. Our clients in the power generation industry include GE, Tennessee Valley Authority, Moventas, Dresser-Rand, Hallibuton, and other industry leaders.

If you would like to explore what NVision can do for your company, please request a quote or contact us.

Please contact us by phone (817.416.8006) or email (sales@nvision3d.com) to discuss your 3D Scanning/Measurement needs.

![]()