Military / Defense / Government

Since its inception more than 30 years ago, NVision has regularly been called upon by the U.S. Department of Defense (DoD) to apply its reverse engineering and inspection capabilities to helping our military better equip and sustain our armed forces. The use of non-contact optical scanning (aka 3D laser scanning) has resulted in better military equipment, accelerated production of replacement parts, improved maintenance through increased inspection accuracy, and much more.

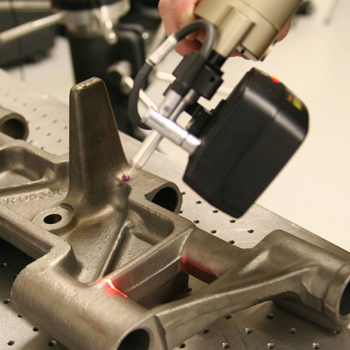

There’s a good reason why the U.S. military, as well as defense contractors, security agencies, and law enforcement, are making greater use of 3D laser scanning: no other technology can inspect and reverse engineer parts of any size or geometrical complexity--from large diesel engines to jet fighter ejection seats to anchorage systems on Coast Guard cutters-- with such unrivaled levels of precision, speed, accuracy, and affordability.

At NVision, each one of our technicians is a field-tested expert with years of practical experience in laser scanning, reverse engineering, computer-aided design (CAD), and inspection/measurement.

Our state-of-the-art scanning can help you:

Keep older military equipment running and enable the creation of spare parts that perfectly duplicate the originals

Keep older military equipment running and enable the creation of spare parts that perfectly duplicate the originals

Much of the United States’ military hardware is already past--or soon will be--its expected life. This creates a critical need for spare parts. To make matters worse, many of the companies that built the parts and equipment have since left the business and/or no CAD files or design drawings exist for these “orphan” parts. Not a problem! We can capture the complex 3D geometry from objects of virtually any size–from an aircraft’s exterior to extremely small parts such as an angle of attack sensor--and quickly reverse engineer them, generating CAD models of the parts, enabling them to be machined to the highest level of accuracy and installed ASAP, maintaining the equipment in peak working condition.

Improve Repair, Maintenance, and Overhaul

Our detailed scanning data and CAD models can help you inspect and repair damaged parts (whether old or new) and improve maintenance and overhaul efficiency by providing you with an accurate “window” to examine otherwise hard-to-access areas of vehicles and equipment.

3D scanning can also be used to create detailed records of repairs made to specific parts and increase part traceability and documentation.

In cases where large structures or transport, such as Navy vessels, need to undergo inspection, laser scanning can greatly reduce or even eliminate the number of military personnel who need to be involved and in close quarters--an important benefit in the age of COVID-19.

Improve your Design, Development, and Manufacturing Processes

When we’ve finished scanning your product, our technicians will use our scanners’ software to convert the data from point cloud form to computer aided design (CAD) file, making it possible to rapidly generate a CAD model that faithfully and accurately duplicates the original part. Using that file, your engineers will be able to easily analyze the product’s design, experiment with possible changes, and ultimately optimize the design to create better-functioning parts, equipment, and weaponry.

We can also compare the original design geometry to the actual physical part, generating an overall graduated color error plot that shows in a glance where, and by how much, the as-built surfaces deviate from the original design. This goes far beyond the dimensional checks that can be performed with other measurement/inspection methods.

Want to 3D print your part? We’ll also provide you with a stereolithography, or STL, file of your part, which you can use to reproduce the part via additive manufacturing, or 3D printing. (STL is one of the most common file formats for 3D printing.)

Do you need to accurately digitize physical prototypes? Some equipment, including types of personal defense apparel, employ a product development process that follows the traditional cycle of building physical prototypes, testing them in the field, reworking them to improve their performance, and then re-testing them, until the performance of the prototype has been optimized. However, it can be difficult to accurately duplicate the geometry of the optimized prototype. Traditional manual measurement methods or coordinate measuring machines (CMMs) generally gather too few data points and do so at a relatively slow rate. In contrast, our laser scanners pick up tens of thousands of data points about the product’s geometry every second. This means that digitizing even the most complicated parts can often be accomplished in an hour or two. Laser scanning can digitize parts that are so complex, it would be impractical to digitize them one point at a time.

Create 3D topographical maps, such as those used by the U.S. Army Corp of Engineers, for use in:

Surveying and construction feasibility studies.

Geological modeling to assess the rate and impact of environmental changes, such as riverbed degradation due to sediment erosion or deposition. Environmental degradation is of growing concern to the DoD, which has stated: "The effects of a changing climate are a national security issue with potential impacts to Department of Defense missions, operational plans, and installation." NVision’s Large-Area scanner, which provides extremely accurate measurements and geo-spatial data about large structures and areas, can be a critical aid in assessing climate-related or other environmental changes that could negatively impact DoD mission effectiveness on its installations or operations.

Upgrade the Design and Effectiveness of Testing Facilities

NVision’s engineering services have been used by NASA and other agencies to inspect and fine-tune the accuracy of wind tunnel and other experimental design models. In evaluating testing facilities, accuracy is critical because the smallest deviation from the original design could substantially alter performance. 3D laser scanning provides the ultra-high accuracy essential to evaluating testing facilities and models.

The need to continuously refine and improve the equipment and weaponry employed by the DoD, Dept. of Homeland Security, law enforcement, and other agencies is a critical one. 3D laser scanning provides the precision, speed, and economy to give those entrusted with our safety and security the tools they need as we continue to advance further into the 21st Century.

For over three decades, the NVision name has been synonymous with quality work. Our experience in the military/defense, law enforcement and government industries shows...in the results we deliver and the customers we keep. Our clients include Lockheed Martin, L3 Communications, the National Institute of Standards and Technology (NIST), Raytheon, and the U.S. Army, Marine Corps, Air Force, Navy, and Coast Guard.

Please contact us by phone (817.416.8006) or email (sales@nvision3d.com) to discuss your 3D Scanning/Measurement needs.