Consumer Products

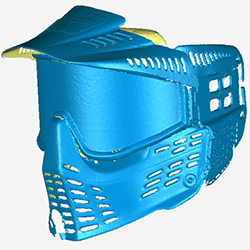

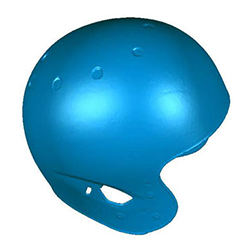

From beverage bottles and bathroom fixtures to custom roof racks, headform models for eyeglasses, and custom gun grips, NVision's non-contact optical scanning and reverse engineering services have helped thousands of manufacturers improve consumer product designs, enhance fit and function, and correct production flaws. The results have been faster, more efficient design and production processes, better products, and greatly accelerated time to market.

Let our experienced scanning technicians help you accomplish your design goals! The same strengths that make 3D scanning the go-to technology for inspection and reverse engineering in other industries--namely, its remarkable accuracy and speed relative to traditional measurement techniques--also come into play with consumer products. There is almost no aspect of the product design or production process that can't be enhanced or improved with 3D scanning, including time to market.

Let our experienced scanning technicians help you accomplish your design goals! The same strengths that make 3D scanning the go-to technology for inspection and reverse engineering in other industries--namely, its remarkable accuracy and speed relative to traditional measurement techniques--also come into play with consumer products. There is almost no aspect of the product design or production process that can't be enhanced or improved with 3D scanning, including time to market.

NVision’s scanners are capable of capturing 3D geometry from objects of almost any size or shape. Our technicians move about the object, capturing data rapidly with an ultra-high degree of resolution and accuracy. As a part is inspected, the scanner generates a “point cloud” consisting of millions of points, each with x,y,z coordinates and i,j,k vectors. Every data point represents a location on the object’s surface. Together, the millions of points represent the complete geometry of the object’s surface, containing every visible detail, many of which would be impossible to obtain by any other inspection method.

After completing the scanning, we polygonate the raw point cloud data into an STL file, which we use as a template to create CAD models, including design-intent models. We’ll provide you with models in IGES and STEP format, which is a generic CAD file, importable into any CAD software. Upon delivery, you can import the IGES/STEP models into your in-house CAD software to analyze, or to interface with existing CAD design models you may have.

Our team of technicians is waiting to help you:

Advance your design goals:

Whether its a prototype with complex geometry or an existing product (even one lacking previous CAD information), our scans will provide you with CAD models that are exact duplicates of the product, down to every curve and contour, which you can use for further design engineering, reproduction, and more.

Improve Production Efficiency by comparing as-built with design intent models:

Before you launch into mass manufacturing, our ultra-accurate scans can reveal how close the as-built product conforms to the design-intent model. Our complete surface inspection can reveal where any deviations lie, enabling you to resolve any production issues quickly without hindering production, helping to keep costs down and get your product to market faster.

Re-engineer legacy parts or parts that are no longer available:

Some consumer products require parts and equipment from suppliers that no longer produce those parts or that are no longer in business. Reverse engineering allows you to recreate those vital parts yourself. Once a designer reverse engineers an object, the model can be transferred into most major CAD software packages to manufacture replacements and incorporate into future designs.

Solve Seal, Fit, Assembly and Functionality Issues:

3D scanning is the fastest, most accurate tool for solving these design engineer headaches. Correcting deviations between an as-built product and its original design can yield huge dividends in product quality and consumer satisfaction. A 3D scan comparison of the as-built product with its original design can clearly reveal the locations, and extent, of defects including sealing issues, warping, bending, twisting, and other deformations, as well as wear, erosion and points of interference hindering fit and assembly. Color deviation maps, which assign different colors to areas with too little/too much materials, precisely pinpoint the trouble areas that need to be addressed.

Convert clay models into 3D CAD models

Many consumer products with intricate contours, such as automobiles and bicycle helmets, are still initially designed by being sculpted in clay. Our team can digitize your clay model for further design work. We can scan and reverse-engineer the initial clay sculpture and convert it to a CAD model. You can then use the CAD model to design additional elements, add embellishments, etc. The CAD model can continue to be used for further analysis and refinements.

For over 30 years, the NVision name has been synonymous with quality work. Our experience with consumer products shows...in the results we deliver and the customers we keep. Our clients include Procter & Gamble (P&G), Kohler, Soft Air USA, Carlisle Foodservice Products, and many more.

Please contact us by phone (817.416.8006) or email (sales@nvision3d.com) to discuss your 3D Scanning/Measurement needs.