Error message

Success Stories, Reverse Engineering, Inspection and Gauging...

Success is defined by results - and we have many stories to tell. Here are just a few...

NVision Featured in Packaging Technology Today

NVision Featured in Packaging Technology Today

NVision President Steve Kersen Explains to Packaging Technology Today How 3D Scanning Can Speed Packaging Design and Certification.

How is inspection/detection/visioning technology changing? What are the key capabilities of this technology? Why is this technology important for the inspection and certification process?

NVision Plays Key Role in Creation of Record-Breaking "Balloon Dog" Sculpture

NVision, Inc., a leader in 3D non-contact optical scanning for over 30 years, played a key role in the creation of the "Balloon Dog (Orange)" sculpture that was recently sold by Christie’s for 58.4 million dollars, setting a record as the most expensive work by a living artist to be sold at auction.

NVision laser-scanned the original balloon dog created by artist Jeff Koons and then produced a 3D CAD model of the dog, which Koons used as a template to create several full-size sculptures in different colors, including orange, red, green, blue and pink. Made of stainless steel and standing an impressive 12 ft. tall, “Balloon Dog (Orange)” is a replica of the type of balloon dog that a vendor might create for a child at a birthday party or county fair. Click here, read more.

NVision provides CAD files for GE Aviation

"Ok, Thank you! We got the CAD files they look really good!"

~ GE Aviation

NVision engineers collect data, created CAD (Computer-Aided Design) models, and provided inspection reports for a wide variety of commercial, industrial, military, and design projects. We have learned to be innovative in method and use of hardware / software in order to make the most efficient use of the available hardware and software to successfully complete the project.

Reverse engineering of turbine saves weeks of time for major turbomachinery engineering firm

Reverse engineering of turbine saves weeks of time for major turbomachinery engineering firm

(October 2013) NVision, Inc. recently reverse engineered the rotor assembly, diffusers and diaphragm of a turbine for a major turbomachinery engineering firm in Texas. The full reverse engineering process only took five weeks, far less than six months that the engineering company had originally allotted for the project using less sophisticated measurement methods. “Using our own HandHeld scanner, we were able to measure the parts’ geometry to extremely high levels of accuracy and produce the necessary CAD files. This made it possible for the company to perform simulations to optimize the turbine’s design, substantially improving its energy efficiency,” said Steve Kersen, NVision's Vice President of Sales and Marketing. Read more, click here.

HandHeld Scanner Helps Ensure Top Quality Production of Aluminum Die Castings for LED Lamps

HandHeld Scanner Helps Ensure Top Quality Production of Aluminum Die Castings for LED Lamps

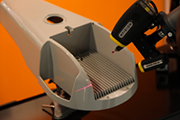

(Coppell, TX; May 2013) - Lighting Science® uses the HandHeld laser scanner from NVision to ensure the dimensional integrity of the extremely complicated castings it purchases and uses in its roadway light emitting diode (LED) fixtures. In the past, it was difficult to inspect the castings because their geometry was too complex for gauges and blocks and they would have taken a long time to program and inspect on a coordinate measuring machine (CMM). Read the complete story here.

NVision Helps Honor a Fallen Hero

NVision Helps Honor a Fallen Hero

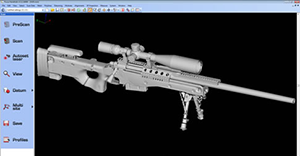

NVision Inc. recently volunteered its 3D laser-scanning services to help Sarasota sculptor Greg Marra create an exact replica of the rifle that former Navy Seal Chris Kyle used while in the military.

Christopher Scott "Chris" Kyle is widely considered to have been the most lethal sniper in U.S. military history with over 150 confirmed kills. Having retired from the military, Kyle and a friend were shot and killed in February at a Texas gun range by another former service member whom they were trying to help cope with post-traumatic stress disorder. (Read more...)

Turbine Parts Supplier Reduces Reverse Engineering Time 60% With NVision Laser Scanner

Turbine Parts Supplier Reduces Reverse Engineering Time 60% With NVision Laser Scanner

Turbine parts supplier Power Plant Services is using an NVision HandHeld laser scanner to reduce by 60% the time required to reverse engineer turbine blades. In the past it took the Melrose Park, Illinois company 15 hours to produce a 3D computer aided design (CAD) file from a customer's turbine blade. But that has now changed. "By switching to NVision's HandHeld laser scanner we can produce an accurate CAD file in only six hours, which makes it possible to deliver a new blade to our customer one full day faster than was possible in the past," said Chad Fisher, Project Manager for Power Plant Services. That time saving can result in significant cost savings for the company's customers.

NVision Helps Purdue Auto Engineering Team Pursue Racing Dream

Purdue University’s Formula SAE team is utilizing NVision's HandHeld laser scanner to pursue its goal of taking home a first-place trophy in the annual Formula SAE Competition. The team anticipates that reverse engineering data obtained by the HandHeld scanner will allow for a strong Purdue showing at the upcoming 2013 competition.

The Formula SAE competition is an annual event sponsored by the Society of Automotive Engineers (SAE) in which teams of SAE student members from about 130 colleges and universities around the world compete to design and manufacture the best all-around small formula-style racing car. The competition’s restrictions on the vehicle frame and engine are limited, which challenges the students’ knowledge, creativity, and imagination. Their goal in the competition is to produce a prototype of a high performance car that is low in cost, easy to maintain, and reliable. Also of concern is the vehicle’s marketability, so the team members must keep in mind factors such visual aesthetics and passenger comfort when they design the cars. The end result of participation is a valuable engineering experience for students and an opportunity to be part of an engineering project requiring a team effort, which often improves students’ skills in time management and communication.

NVision Scanner Plays Key Role in Ground Zero Special Forces Monument

Synappsys Digital Services, a sculpture enlargement and reduction company based in Norman, OK, used NVision’s 3D HandHeld laser scanner to create the model for a sculptured tribute to U.S. Special Forces in Afghanistan that is now on display near Ground Zero in New York City.

In the wake of the September 11 terrorist attacks, President George W. Bush dispatched Task Force Dagger to Afghanistan. The task force is a joint Special Operations team consisting of Green Berets from the 5th Special Forces Group, aircrew members from the 160th Special Operations Aviation Regiment, and Air Force Combat controllers. The men were offered horses by the Afghan tribes they were supporting and rode into battle with the Afghan Northern Alliance against the Taliban. When sculptor Douwe Blumberg of DeMossville, Kentucky, saw a photo of the Special Forces soldiers fighting on horseback in Afghanistan he was moved to create a sculpture. He spent nine months creating an 18 inch tall clay model called a maquette.

NVision’s Scanning Service Helps Soft Air USA® Get Replica Airsoft Guns to Market Faster, Boost Sales 25%

NVision’s Scanning Service Helps Soft Air USA® Get Replica Airsoft Guns to Market Faster, Boost Sales 25%

Soft Air USA®, Inc has reduced the time required to get its licensed replica airsoft guns to market by 4 to 6 weeks by using NVision’s laser scanning service bureau to reverse engineer the real guns. The real guns can’t be shipped to Asia where the replicas are manufactured, so in the past the manufacturers would travel to the U.S. to make silicone molds. Now, NVision’s laser scanning service bureau uses laser scanning to produce a computer aided design (CAD) file of the gun’s geometry. “Laser scanning helps us get our guns to market faster, which typically results in a 25% increase in the revenues generated by each product,” said John Steele, President of Soft Air USA®.

NVision Saves OEM 4-1/2 Months in Reverse Engineering Steam Turbine

NVision Saves OEM 4-1/2 Months in Reverse Engineering Steam Turbine

NVision’s Contract Service Division recently reverse engineered the complete core of a steam turbine for a major original equipment manufacturer (OEM) in only 6 weeks compared to the 6 months that the OEM had budgeted for the project using less sophisticated measurement methods. “Measuring the critical blade geometry to high levels of accuracy made it possible for the turbine manufacturer to perform simulations that helped to redesign the blades and diaphragms to substantially improve the energy efficiency of the hundreds of existing turbines,” said Steve Kersen, President of NVision.

TGTC Endorses MAXOS Technology with First Purchase as Inspection Time is Reduced by 83%

TGTC Endorses MAXOS Technology with First Purchase as Inspection Time is Reduced by 83%

Toshiba GE Turbine Components (TGTC) has reduced the time required to inspect and measure steam turbine blades from 280 minutes to 45 minutes by using the MAXOS non-contact measurement system.

Laser Scanner from NVision Reduces Cost to Produce Flight Simulator Ejection Seats

Laser Scanner from NVision Reduces Cost to Produce Flight Simulator Ejection Seats

Fain Models uses NVision's HandHeld Laser Scanner to produce accurate copies of jet fighter ejection seats for use in the flight simulation and training markets for significantly less than the cost of the flight worthy seat. Fain technicians use the NVision scanner to capture the 3D geometry of the more than 100 components in the seat and then use the geometry to machine the seats or models used to make molds. "The NVision HandHeld Scanner is ideal for this application because it can freely move around an object to capture data at any angle at a very high resolution," said Cris Runge, Scanning and Reverse Engineering Manager for Fain Models.

NVision’s Services Help K9 Training Company Support Military and Homeland Security

NVision’s Services Help K9 Training Company Support Military and Homeland Security

Using NVision’s laser scanning and engineering services has helped a manufacturer of K9 training equipment save time and money while increasing the accuracy with which it can digitize prototypes. The result has been better products produced in less time at less cost. “I have become convinced of the value of laser scanning,” said Guy Hairston, President of Harddog’s Requisites. “I have also seen first-hand the dedication of NVision’s people to meeting their customers’ needs and would recommend them highly to anyone who needs a first-rate laser scanning service bureau.”

Using NVision Laser Scanner Corrects Aluminum Casting Distortions, Saving Two Months Time

The aluminum casting was left too long in an oven where a heat treating operation was being performed. The oven distorted the geometry to the point that operators for the subsequent machining operation felt that they would be unable to make a good part. The distortion reached the level that they were not able to even determine an orientation that the part could be placed in that would eliminate the need to add material to achieve required dimensions. The part could have been recast but that would cost $5,000, taken two months, and delayed the delivery of the finished product to the customer by nearly that long.

The solution turned out to involve an innovative use of NVision's laser scanner.

NVision - A Better Reverse Engineering Approach When Modifying Molds

Tennessee Watercraft, Inc. (TWI) is enjoying significant time and money savings by using NVision’s laser scanning service to speed the process of robot programming. The company has found that NVision’s scanning service easily pays for itself by cutting an estimated $150,000 off the cost of robot programming, a reduction of ±60 percent. The laser scanning also has greatly reduced the time required for programming.

Tier One Supplier Benefits From NVision Laser Technology

Laser technology was used to generate a solid model of a 53-foot trailer with significantly less time and money than would have been needed to do the job by hand.

The "virtual" model was created to test heavy vehicle components produced by a leading tier one supplier for automotive, commercial, and off-highway vehicles. A CAD operator would normally need several months to create such a large simulation model. Instead, the supplier contracted NVision Inc. to model the trailer using laser scanning and laser tracking technology. The model is now being used to refine the design of the supplier's truck components at an earlier stage in the development process, which reduces "time to market"

NVision Service Reduces Airbag Cover Reverse Engineering Project By 12 Weeks

Recently, a tier one automotive supplier asked Hunt Machine and Manufacturing to build a mold to produce an enhanced version of an existing interior trim component that sits on the top of the airbag module in an instrument panel. “The challenge came from the fact that we were given this task without any historical data that anyone felt comfortable with.” Hunt said. The part was so soft and flexible that it would have been impossible to use a contact measurement method to determine its geometry. It would have been possible to measure the mold using a contact measurement method but this would have created the challenge of somehow backing out the shrinkage allowance for the original material and adding the shrinkage allowance for the new material. In addition, there were intricate cursive graphics on the part that would have been nearly impossible to reproduce using a CMM.

Hunt looked for an alternative method of digitizing the part. “I was particularly impressed with the NVision people,” Hunt continued. “They seemed to have the best technology and the deepest talent.”

Seating Manufacturer Promotes Design Re-Use With NVision's Reverse Engineering Services

Track Seating, a stadium seating manufacturer, has improved its ability to re-use previous designs by using laser scanning to reverse engineer existing seats. The company frequently has the need to build new tooling for or make revisions to products that were designed before computer aided design (CAD) systems were available. In the past, it took weeks to capture geometrical data from the old products point-by-point with a coordinate measuring machine (CMM). More recently, the company began using a laser scanning service bureau to reverse engineer the seats. The bureaus’ scanner generates a point cloud consisting of millions of data points in minutes. This dramatically reduces the cost and time required while also generating a file that represents the contours of the seat to a much higher level of accuracy.

Manufacturer Uses NVision Laser To Get The Perfect Fit

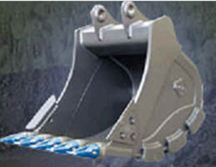

Hensley Industries (Dallas, Texas), which builds ground engaging tools for the construction and mining industries, is saving a significant amount of time and money by using an NVision laser scanner to verify that its replacement parts will fit existing equipment just as well as do its original parts.

One of the greatest challenges for Hensley in building replacement parts for a wide range of equipment is the need to build teeth and adaptors that fit perfectly with the installed base of existing equipment. As they introduced a new product line recently, Hensley engineers wanted to verify that it’s mating geometry was the same as that of its previous product line.

NVision Helps Engineering Services Optimize A New Rear Wing For Ferrari LeMans In Six Weeks

After changes in the GTS rules for the 2003 world famous Le Mans 24 hour race, Veloqx Prodrive Racing were faced with a mandatory reduction in engine power. This rule change, combined with an increase in competition for this year’s race, meant that any possible improvements in the aerodynamic performance of the rear wing, primarily drag reduction, would play a major role in the success of the car.

Given that the project was outlined in early March and with race day fast approaching, there were very few opportunities remaining for actual testing. In fact there was only sufficient time for one wing design to be tested prior to the pre-qualifying event in May.