NVision will be featured in the Nov/Dec 2023 issue of Vision Systems Design Magazine

See a preview of the article: "Artist Gives 19th Century Sculpture 21st Century Perspective With 3D Imaging"

See a preview of the article: "Artist Gives 19th Century Sculpture 21st Century Perspective With 3D Imaging"

NVision Featured in Manufacturing Engineering Magazine

Reverse Engineer Obsolete Parts with 3D Scanning - “part obsolescence,” wherein a previously available part is permanently dropped, can bring a world of headaches.

Reverse Engineer Obsolete Parts with 3D Scanning - “part obsolescence,” wherein a previously available part is permanently dropped, can bring a world of headaches.

3D Laser Scanning Enables Unique Reimagining of 1863 The Freedman Sculpture

3D laser scanning from NVision made possible a remarkable “collaboration” between two sculptors separated by 160 years. The Southlake, Texas company’s precision scanning enabled artist Hugh Hayden to create a new, 3D-printed, version of John Quincy Adams Ward’s groundbreaking sculpture.

3D laser scanning from NVision made possible a remarkable “collaboration” between two sculptors separated by 160 years. The Southlake, Texas company’s precision scanning enabled artist Hugh Hayden to create a new, 3D-printed, version of John Quincy Adams Ward’s groundbreaking sculpture.

NVision Featured in Aerospace & Defense Technology

No doubt there are many manufacturers who don’t fully understand 3D scanning and its capacity to improve the quality and speed of their output. This article addresses the most frequently asked questions about the use of 3D scanning and how it can help manufacturers establish shorter design and production timetables among other improvements.

No doubt there are many manufacturers who don’t fully understand 3D scanning and its capacity to improve the quality and speed of their output. This article addresses the most frequently asked questions about the use of 3D scanning and how it can help manufacturers establish shorter design and production timetables among other improvements.

NVision Featured in Packaging Technology Today

NVision President Steve Kersen Explains to Packaging Technology Today How 3D Scanning Can Speed Packaging Design and Certification.

NVision President Steve Kersen Explains to Packaging Technology Today How 3D Scanning Can Speed Packaging Design and Certification.

Tasked with multiple responsibilities, including the need to meet tight tolerances, reduce material waste, and obtain prompt certification, more packaging manufacturers today are finding their one-stop solution in 3D non-contact optical scanning.

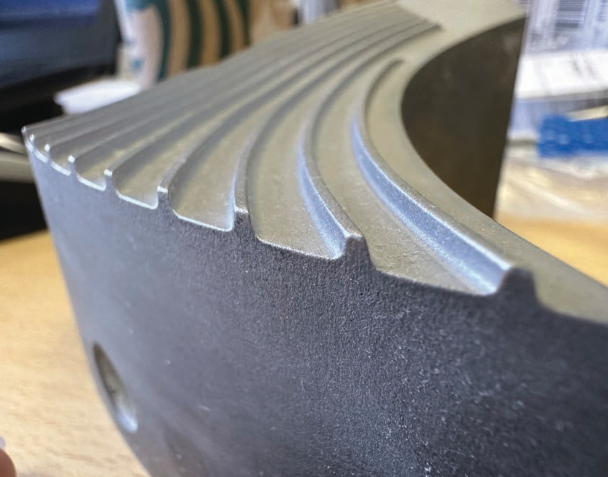

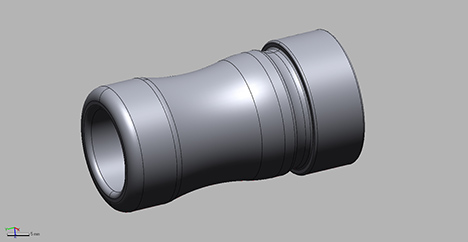

3D Scanning Accelerates RedBone Production of World-Champion Goose Calls

CAD model of goose call insert

(Southlake, Texas; September 24, 2021) -- NVision’s 3D laser and computed tomography (CT) scanning services are helping RedBone, a manufacturer of hand-crafted goose calls, get its unique products to customers faster, enabling the Elton, La., company to significantly expand its output. After scanning two key components of a call--the barrel and the insert--NVision (Southlake, Texas) provides RedBone with computer-aided design (CAD) files containing all the dimensional details of the hand-built parts, which are then used for reproduction. As a result, RedBone has been able to grow its business while ensuring that every replicated part perfectly matches the specific dimensions of the hand-built original.

A bird-damaged Southwest Boeing 737 returns to service in 48 hours

Dallas, Texas - A Southwest Boeing 737, which was damaged by a bird strike, returned to service just in two days thanks to the quick work by NVision Inc., a 3D non-contact optical scanning and measurement company. The rapid turnaround helped Southwest avoid the financial losses caused by grounding an aircraft for a long period. Bird strikes cost airlines billions of dollars each year. Not only because of the damage, but also the incurring capacity loss due to the grounded aircraft.

Read more at one of the following links:

Reverse Engineering parts and systems enable aircraft to keep flying or machines to keep running

NVision's Reverse Engineering capabilities featured in Quality Magazine. Many new industries are employing 3D scanning not only to create 3D models of parts or products for reverse engineering but also to explore the composition and rapid production of ready to use parts via 3D printing. Please click here to read the complete article composed by Steve Kersen, President of NVision3D.

UPDATE ON G-SPEED Project: UNLIMITED CLASS VIPER

The high-accuracy 3D scanning performed by NVision in the fall of 2015 was a key factor in creating the Unlimited Class Viper - one of the most heavily modified second generation Vipers ever. The Viper you guys scanned last year is doing great! ~ J.S. Design Engineer

Watch the Viper SU90 at the Hallett NASA TX Summer Shootout Race 2.

CT Inspection From NVision Helps Bottler Eliminate Sealing Flaws

NVision, Inc., recently used its CT inspection and reverse engineering services to help a leading beverage manufacturer resolve sealing flaws in its large-sized bottles. NVision, a leader in U.S. reengineering services and technology, used its advanced computed tomography (CT) scanning technology to inspect the sealing surfaces of the bottles and reverse-engineer them so that the sealing problems could be isolated and resolved.

NVision 3D Scanning Accelerates Development of Unlimited Class Viper

GSpeed (Cresson, Texas) contracted with NVision, Inc. to 3D-scan the chassis of a Dodge Viper as a key step in GSpeed's goal of building what is expected to be among the fastest Vipers in racing history. The high-accuracy 3D scanning performed by NVision was a key factor in creating the Unlimited Class Viper - one of the most heavily modified second generation Vipers ever.

NVision Influences Science Behind Jurassic Series

3D scanning has helped provide some of the real science behind the Jurassic Park series, says Steve Kersen, President of NVision, Inc. Paleontologist Jack Horner, a lead consultant on the series and inspiration for the series's character Dr. Alan Grant, bought his first 3D scanner from us when the process of digitizing bones and fossilized skin impressions was still in its infancy. Scanning fossils has helped advance our understanding of dinosaurs and how they lived. Much of that knowledge has been used in the Jurassic Park series, including the current blockbuster, Jurassic World.

3D laser scanning a dinosaur fossil can reveal a great deal of the animal's physiology. For example, a scanned bone that reveals scars where muscles were once attached can tell scientists about the type and function of muscles the dinosaur possessed and aid in understanding the animal's biomechanics how it walked or ran, how powerful its bite was.

NVision's Engineering Advances Design of Medical Implants and Surgical Tool

Two major medical developers recently utilized NVision Inc.'s 3D non-contact laser scanning and engineering expertise to improve the design of their surgical products. In each case, NVision laser-scanned and quickly delivered a highly accurate 3D CAD model to the manufacturer, which was then used to help redesign the product.

In the field of breast augmentation surgery, mandrels are molds that are used to create implants of specific shapes and sizes, such as a teardrop or a round contour. A major developer of breast implants was lacking the CAD files for a series of mandrels with highly complex curvatures and contacted NVision to scan and create 3D CAD files of the existing mandrels. "Without the CAD files for the mandrels, it was impossible for the manufacturer to reproduce or redesign the original implants," says Steve Kersen, President of NVision.

Sculpture Honors American Sniper Chris Kyle

(Coppell, TX; February 2015)-- Steve Kersen of NVision Inc. is pleased that Americans are being moved by the movie American Sniper, which tells the story of Navy SEAL Chris Kyle, who, with 160 confirmed kills, is recognized as America's most successful sniper. Prior to the film, NVision participated in honoring the soldier by assisting in the creation of a life size statue of Kyle.

Kyle, portrayed in the Clint Eastwood-directed movie by actor Bradley Cooper, served four tours of duty in Iraq and received numerous medals and commendations for his combat service before his tragic shooting death at the hands of a fellow veteran in 2013.

NVision Helps Aircraft Repair Station Quickly Obtain FAA Approval

(Coppell, TX; December 2014) 3D laser scanning from NVision helped a certified Federal Aviation Administration (FAA) repair station document its work on a passenger jet part with such precision that the station was able to obtain the necessary FAA approval for the repair in much less time than is usually required.

The station brought the part to NVision, a leader in 3D laser scanning and reverse engineering for over 30 years, so NVision engineers could 3D map its exact geometry both before and after the corrosion was removed. The station had worked with NVision on other projects and knew they would be the right company to assist them.

NVision's Consulting and Engineering Services Improve Fracking Parts

(Coppell, TX; October 2014) A major manufacturer of hydraulic fracturing components for the oil and gas industry utilized NVision's full spectrum of engineering services, from consulting to 3D scanning, CAD modeling and 3D non-contact inspection, to improve the design of crucial parts and speed their certification. NVision was able to compare multiple versions of the same parts and determine geometric variation between the versions that passed tests and those that failed. That information was then used by NVision engineers to develop new 3D CAD models with critical dimensions and tolerances, leading to improved designs and faster certification of the parts.

NVision 3D Scanning Speeds Up Drag Boat Racing

(Coppell, TX; September 2014) NVision, Inc., a leader in 3D laser scanning and reverse engineering for over 24 years, has announced that it was able to help a motorsports boat designer optimize the design of the custom-built propellers created for its Top Fuel Hydro drag boat. The boat maker sent the propellers to NVision, where engineers 3D mapped them with the company’s HandHeld scanner to capture all their geometrical information within a tolerance of +/- .001".

Heavy Equipment Manufacturer Saves Money and Improves Quality with NVision 3D Scanner

(Coppell, TX; July 2014) A heavy equipment manufacturer with facilities throughout the world has improved the dimensional accuracy of its ground engagement tools by using an NVision HandHeld laser scanner to measure tooling and finished products with a higher degree of accuracy than was possible in the past. Measuring these tools is challenging because of the complexity of their shapes, tight dimensional tolerances and harsh manufacturing environment. We have significantly lowered our reject rate and improved our ability to hold close tolerances by using the HandHeld laser scanner to generate complete 3D geometry at all stages of the product development process, said a 3D Scan Technician for the manufacturer.

Manufacturing News features 3D Scanner by NVision and it's role in improving quality of heavy equipment manufacturer.

Overview: The purposes for reverse engineering are many and varied, ranging from the need to reproduce an existing product lacking CAD documentation to acquiring sensitive information to determine possible patent infringement.

(May 2014) - Many ideas can spring to mind when one hears the term reverse engineering. Some think of it as a form of corporate espionage, a means to copy competitors parts, others regard it primarily in terms of their own immediate industrial needs, as in the case of an electronics manufacturer using reverse engineering to replicate printed circuit boards (PCBs). However, the purposes for reverse engineering are many and varied, ranging from the need to reproduce an existing product lacking CAD documentation, which we discuss later, to acquiring sensitive information to determine possible patent infringement. Read the complete article featured on Quality Magazine.

NVision Saves Misfit Industries Time and Money in Design of Custom Harley Parts

(Coppell, TX, April 2014) NVision, Inc. helped Misfit Industries save considerable time and money bringing its new line of Harley Davidson custom parts to market. Misfit recently converted many of its parts from composites to aluminum and steel in order to reduce labor costs and production leadtime. NVision's scanning and CAD modeling services helped Misfit reverse-engineer the previous generation parts, factory parts, and sections of the motorcycles that interface with the parts. The resulting computer aided design (CAD) models were then provided to the die maker, substantially compressing the design cycle. The reverse engineering process also ensured that each custom part interfaced seamlessly with previous and new generation Harley models.

NVision Introduces RoboScanner, The World's Fastest, Portable Robotic Scanner

(March 2014) - NVision is excited to introduce the RoboScanner, a lightweight, turn-key laser scanning system that offers fully automated scanning with 3D analysis. The RoboScanner provides a significantly faster way to accurately measure components in a production environment, said Steve Kersen, President of NVision.

Until now industrial robots were large, heavy, stationary, and expensive. The RoboScanner comes with none of these disadvantages. Weighing only 50 pounds and being touch-sensitive, it avoids the need for the safety cage required by larger, immobile, high-force robots. In addition, the scanner provides instant inspection analysis and key performance advantages in speed, accuracy, and ease of use.

"3D Measurement: The Basics": NVision interview featured in recent Quality Magazine

There are good reasons why traditional contact measurement machines (CMMs) have been staples in manufacturing's quality control environments for decades. These machineswhich collect data points wherever a probe meets a surfaceare known for generating high-accuracy measurements and automation abilities. But since they are expensive, stationary tools, they can leave something to be desired.

Click here to read the article on Qualitymag.com.

NVision Partners with CAD/CAM Connect to Bring Engineering and Measurement Services to Industry

(January 2014) - NVision, Inc., a leader in 3D non-contact optical scanning for over 30 years, has teamed with design/manufacturing website CAD/CAM Connect (CADCAMConnect.com) to help bring its inspection and reverse engineering solutions to companies in need of those services.

CAD/CAM Connect partners with leading CAD/CAM/CAE product and service providers such as NVision and offers industry news, trends, user forums and discussion groups, and various deals on different products.

NVision Plays Key Role in Creation of Record-Breaking "Balloon Dog" Sculpture

NVision, Inc., a leader in 3D non-contact optical scanning for over 23 years, played a key role in the creation of the "Balloon Dog (Orange)" sculpture that was recently sold by Christie's for 58.4 million dollars, setting a record as the most expensive work by a living artist to be sold at auction.

NVision laser-scanned the original balloon dog created by artist Jeff Koons and then produced a 3D CAD model of the dog, which Koons used as a template to create several full-size sculptures in different colors, including orange, red, green, blue and pink. Made of stainless steel and standing an impressive 12 ft. tall, Balloon Dog (Orange) is a replica of the type of balloon dog that a vendor might create for a child at a birthday party or county fair.

Reverse engineering of turbine saves weeks of time for major turbomachinery engineering firm

NVision, Inc. recently reverse engineered the rotor assembly, diffusers and diaphragm of a turbine for a major turbomachinery engineering firm in Texas. The full reverse engineering process only took five weeks, far less than six months that the engineering company had originally allotted for the project using less sophisticated measurement methods. Using our own HandHeld scanner, we were able to measure the parts geometry to extremely high levels of accuracy and produce the necessary CAD files. This made it possible for the company to perform simulations to optimize the turbine's design, substantially improving its energy efficiency, said Steve Kersen, NVision's Vice President of Sales and Marketing.

Laser Scanning services by NVision (a leader in 3d non-contact optical scanning) helps expland product line, featured on CAD/CAM Connect

NVision's Engineering Service Division is laser-scanning objects selected by ReadeREST, creating computer aided design (CAD) models of new clip designs, and then using 3D printing to produce prototypes of the new designs, click here to read more.

Non-contact Laser Scanning services by NVision help expland product line and improve efficiencies, featured on Lidar News

Hopper contacted NVision, a leader in 3D non-contact optical scanning for over 23 years. NVision solved the problem by quickly and inexpensively laser-scanning the objects that Hopper had in mind. The company also scanned ReadeREST's existing product and merged decorative models with the current product model to create a number of new designs. After scanning, NVision engineers converted the resulting point clouds into solid models then used a 3D printer to produce prototypes of the designs. Click here to read more.

Handheld Scanner Improves Quality of Complex Castings for LED Fixtures

Lighting Science uses the HandHeld laser scanner from NVision to ensure the dimensional integrity of the extremely complicated castings it purchases and uses in its roadway light emitting diode (LED) fixtures. In the past, it was difficult to inspect the castings because their geometry was too complex for gauges and blocks and they would have taken a long time to program and inspect on a coordinate measuring machine (CMM). Read the complete article featured on Mold Making Technology, click here.

Using CT Scanning to Test / Inspect Medical Devices in the Design or Production Phase

NVision featured on NASA's TechBriefs in article spotlighting the use and continued growth of CT scanning for test and inspection of medical products. The rapid advance of medical technology has created a growing need for ever more precise technologies to measure and inspect medical components. One of the most accurate scanning technologies, and one whose use is growing in the medical equipment community, is CT scanning. Click here to read the article.

Laser scanning by NVision provides computer aided design (CAD) model and 3D printing for "Shark Tank" winner

(Coppell, TX, September 2013) - NVision, Inc. is helping ReadeREST, a recent winner on the ABC TV show 'shark Tank, expand its line of magnetic reading glass clips by quickly and efficiently modeling common objects so they can be used as the basis for creating decorative new clip designs. NVision's Engineering Service Division is laser-scanning objects selected by ReadeREST, creating computer aided design (CAD) models of new clip designs, and then using 3D printing to produce prototypes of the new designs. NVision's laser scanning is making it possible for us to economically expand our product line by developing magnetic clips that appeal to specific market segments, such as a ribbon for breast cancer awareness, said Rick Hopper, President of ReadeREST.

The leader in non-contact optical scanning, NVision, featured on Quality Digest in article entitled "NVision Saves Clients Time and Money with Consulting-First Approach."

(August 2013) - Nvision offers advice on what's more cost-effective: purchase equipment or outsource 3d scanning needs. "At NVision, we work by first consulting in-depth with a prospect, learning their needs, then advising them as to whether it is more cost- effective for them to purchase equipment or whether it is better to outsource. We believe this consulting makes NVision unique and has saved customers time and money," says Steve Kersen, NVision's VP of Sales & Marketing.

"Choosing the Right Scanning Technology for Reverse Engineering", NVision article featured on CAD/CAM Connect and CATIA Community

Benefits of scanning technology for reverse engineering include:

(July 2013) - Once a part is scanned in and converted, the computer models are then used to create duplicates of the original part (or, in the case of long-range scanning, the structure), analyze and optimize the original part, or - if used for inspection - to show deviations between the manufactured product and the original 3D design. After scanning is completed, the object's 3D data is usually converted to an STL file, which is then used to create a 3D IGES/STEP/parasolid model or native solid in the specific CAD format required. These formats include CATIA, Pro/Engineer (Pro/E), SolidWorks, Inventor, Unigraphics/NX, and SolidEdge.

Non-contact scanning consulting services save companies time and money

(August 2013) - Unfortunately, most companies just want to focus on selling their scanning equipment or their scanning service. They dont really take the time to assess the prospect's needs in the long-term and decide on what is truly the best course of action for the customer, time and money-wise, says Steve Kersen, NVision's VP of Sales & Marketing. At NVision, we work by first consulting in-depth with a prospect, learning their needs, then advising them as to whether it is more cost- effective for them to purchase equipment or whether it is better to outsource. We believe this consulting makes NVision unique and has saved customers time and money.

HandHeld Scanner Helps Ensure Top Quality Production of Aluminum Die Castings for LED Lamps

(Coppell, TX; May 2013) - Lighting Science® uses the HandHeld laser scanner from NVision to ensure the dimensional integrity of the extremely complicated castings it purchases and uses in its roadway light emitting diode (LED) fixtures. In the past, it was difficult to inspect the castings because their geometry was too complex for gauges and blocks and they would have taken a long time to program and inspect on a coordinate measuring machine (CMM).

NVision Scans Sniper Rifle from Fallen Hero

(April 15, 2013) - 3D laser scanning used to scan rifle of Navy Seal Chris Kyle - 3D scan was used to create exact replica of rifle for use on statue honoring Chris Kyle.

NVision Helps Honor a Fallen Hero

(April 2013) - 3D Laser Scanning with a handheld scanner by NVision featured on The American Surveyor. NVision Inc. recently volunteered its 3D laser-scanning services to help Sarasota sculptor Greg Marra create an exact replica of the rifle that former Navy Seal Chris Kyle used while in the military. Using the company's HandHeld laser scanner, NVision technicians scanned the gun, collecting all the necessary data on the rifle's exact shape and size. Read the complete story here.

A Life Remembered, NVision Helps Honor a Fallen Hero

(April 2013) - NVIsion volunteers handheld scanner for 3D Laser Scanning to help Sarasota sculptor Greg Marra create an exact replica of the rifle that former Navy Seal Chris Kyle used while in the military. This HandHeld scanner is often used in contract inspection projects and is capable of capturing 3D geometry from objects of almost any size or shape. Read the complete story here.

NVision Helps Honor a Fallen Hero

(April 2013) - 3D scanner by Nvision helps create an exact replica of the rifle that former Navy Seal Chris Kyle used while in the military. This HandHeld scanner is often used in contract inspection projects and to reverse engineer products and is capable of capturing 3D geometry from objects of almost any size or shape. Read the complete story featured on Lidar News.

3D Handheld Scanner Helps Honor a Fallen Hero

(April 2013) - 3D scanner by Nvision helps create an exact replica of the rifle that former Navy Seal Chris Kyle used while in the military. This HandHeld scanner is often used in contract inspection projects and to reverse engineer products and is capable of capturing 3D geometry from objects of almost any size or shape. Read the complete story featured on ECN Magazine.

Product Design and Development spotlight: NVision Helping to Honor a Fallen Hero

(April 2013) - Using the company's HandHeld laser scanner, NVision technicians scanned the gun, collecting all the necessary data on the rifle's exact shape and size. Kyle’s wife allowed NVision to use her husband’s gun for the project. This HandHeld scanner is often used in contract inspection projects and to reverse engineer products and is capable of capturing 3D geometry from objects of almost any size or shape. Read the complete story featured on Product Design and Development.

(April 2103) - NVision featured on Product Design and Development, article entitled "Robots Blaze New Path for Glaze"

The handheld scanner by NVision scanned a number of one-piece toilet bowls and tank combinations for an equipment manufacturer. The data obtained from the 3D scanner was then converted to a CAD format for programming the robot path. The robot would be used to spray enamel on the exterior and bowl surfaces of a new product. Read the complete story on Product Design and Development.

NVision featured in Medical Design Briefs, article entitled "Using CT Scanning to Test / Inspect Medical Devices in the Design or Production Phase" (April 2013)

News Archives

NVision Increases Medical CT Scanning Projects (November, 2012)

NVision Helps Purdue Auto Engineering Team Pursue Racing Dream (September 18, 2012)

NVision Featured In Product Design & Development's Enewsletter (August 17, 2012)

NVision Scanner Plays Key Role in Ground Zero Special Forces Monument (July, 2012)

NVision Featured In LiDAR Article On Aerospace Reverse Engineering (June, 2012)

NVision Featured In Medical Design Technology Article (June, 2012)

NVision Featured In Inventor Connections Article (May, 2012)

NVision Launches New Project Portal (April 12, 2012)

NVision Featured in Fabricating & Metalworking (March 21, 2012)

Mississippi Polymer Institute Acquires NVision Scanner (March 14, 2012)

NVision Helps Sculptor Generate Additional Revenue From His Art (January, 2012)

NVision Helps Reverse Engineer Optical Store Display (December 1, 2011)

NVision Featured in Article in Vision Systems (November 10, 2011)

NVision Featured in Article on Reverse Engineering And Training (November 8, 2011)

NVision Featured in Quality Digest (October 26, 2011)

NVision Saves Toilet Manufacturer $20,000 and Four Weeks In Developing New Model (October 25, 2011)

NVision Part of Rapid Field Assistance in Science and Technology Center (RFAST-C) At Bagram Air Base in Afghanistan (October 18, 2011)

NVision Helps Recalibrate CT Scanner - Prototype Today (September 28, 2011)

NVision Featured In Quality Digest Article On Reverse Engineering Of Key Impeller At Hydroelectric Plant (August 24, 2011)

NVision Featured In Vision Systems Design On Reverse Engineering Of Key Impeller At Hydroelectric Plant (August 15, 2011)

NVision Featured In Quality Magazine Case Study (August 1, 2011)

NVision Featured In Distrbuted Energy Article (June 23, 2011)

NVision Now Offers Product Defect Analysis (June 9, 2011)

NVision Specialized Training Assists Navy's Reverse Engineering (May 5, 2011)

NVision Now Offering Industrial CT Scanning (February 23, 2011)

NVision Featured in PRO/Engineer Article (October 25, 2010)

NVision Looks To Galvanize Reverse Engineering Market (September 21, 2010)

Delta Airlines Improves Blade Mainenance With MAXOS System From NVision (May 4, 2010)

NVision Receives Defense Funding (March, 2010)

Upgrading Older Steam Turbines (Power Engineering - March, 2010)

Toshiba GE Turbine Components Purchases 2nd MAXOS Measurement System (May 6, 2009)

Scanned And Delivered: Replica Gun Sales Boosted 25% (March 10, 2009) (DesignFax)

CFD Saves Time in Reverse Engineering a Steam Turbine (February 2009) (Design World)

NVision Helps OEM Save 4-1/2 Months In Steam Turbine Engineering (November 11, 2008)

NVision Expands Detroit Office To Meet High Demand For New Inspection System (October 25, 2007)